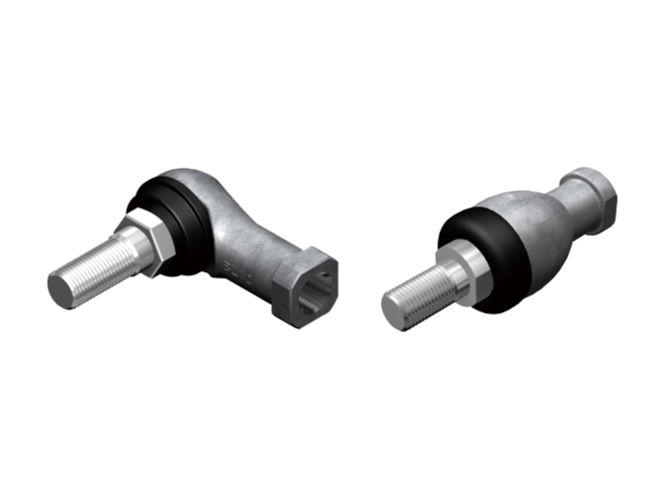

Noise-Reducing THK BL Link Ball with High Load Capacity

Experience the most precious quality, THK BL Link Ball, accurately designed and manufactured for the high load capacity and noiseless performance. It always provides the top durability.

Product Introduction

The THK BL Link Ball is a combination ball stud and spherical sliding bearing that connects moving parts with little play. A precision-machined steel ball bearing is inside the die-cast holder and sealed boot. This lets the holder move smoothly even when it is under a lot of weight. A high-strength zinc alloy holder or an A-1 aluminum alloy for lighter versions connected perpendicularly to the carbon steel ball shank ensures that the BL series is tough and lasts a long time. The grease pockets on the top and bottom of the spherical area keep the assembly well-lubricated all the time. This cuts down on noise and friction a lot. The BL Link Ball is great for rod ends on vehicle height sensors and other precise machines that need to run quietly because it is sealed and always lubricated.

Recommended Products & Advantages

THK BL 16BD Link Ball

This THK BL Link Ball model is heavy-duty and has an M16×2 thread, which gives it the most strength and stability. The chromate-treated steel ball shank and strong zinc alloy holder make it very hard to wear down. Lithium grease pockets and a sealed NBR boot make it easy to move, even when it’s full. Because it is small and has a holder that is perpendicular to the axis, the BL 16BD can easily resist axial and radial forces.

- Material: The parts are an NBR rubber boot for sealing, a zinc alloy holder, and a steel ball shank with a chromate finish and an HV of at least 650.

- High Load: The static capacity is 36,400 N for big loads, and the yield strength is 26,900 N.

- Precision: To reduce play, the spherical clearance is 0.02–0.06 mm radially and ≤0.3 mm axially.

- Lubrication: The top and bottom both have grease chambers that are already filled with lithium-soap grease to help reduce friction.

- Applications: Helpful when you need to be quiet, like when you’re working with heavy link movements in robotics and automation.

THK BL 16D Link Ball

This version uses the M16×1.5 thread, which is similar to the 16BD model. The holder, which is made of a strong zinc-alloy, the ball shank, which is made of carburized steel, and the sealed NBR boot are all part of the same strong structure. This little male thread is perfect for setups that need a regular right-hand screw.

Compact Holder: This small holder has grease channels and is very slippery.

Load Specs: It can handle a static load of 36,400 N and a radial load of 26,900 N.

The small ball clearance guarantees a secure, tight fit.

Precision Fit: The boot and grease pockets inside the machine help keep noise down when it is moving.

Quiet Operation: This technology is often used in machine linkages and mechanical levers for tasks that need reliable, quiet movement.

THK BL 14BD Link Ball

The M14×2 thread type is a medium-sized thread that is still strong. The holder is made of a strong zinc alloy, and the steel ball shank has been hardened to make it stronger. The NBR boot and the oil inside make it easy to move.

- Durable Design: A holder made of zinc alloy and a chromium-treated steel ball shank.

- The tight clearance should be between 0.02 and 0.06 mm radially and less than 0.3 mm axially for precise motion control.

- Load Capacity: Even though it is small, it can hold up to 36,400 N of static stress and 19,800 N of yield strength.

- Self-Lubricating: Grease pockets automatically keep the joint lubricated, which means less maintenance is needed.

- Versatile: Useful in many situations, like industrial machines, assembly lines, and anything else that needs a strong connection.

THK BL 14D Link Ball

The materials used in this standard model (BL14BD) are the same as those used in the M14×1.5 thread. It can still handle loads of 36,400 N static and 19,800 N yield, even though it has a simpler right-hand thread design.

High-Strength Materials: The zinc-alloy housing and the hardened steel ball are both very strong.

Compact Precision: Get a sealed boot that works quietly and fits tightly around the sphere with high accuracy.

Load Ratings: The BL14BD has a static load capacity of 36,400 N.

Easy Installation: M14 thread, standard, right-hand; caps with an “L” on them show left-hand versions.

Applications: These joints and link mechanisms are great for equipment because they are strong and work smoothly.

Add Your Heading Text Here

Low-Noise Operation

The BL Link Balls have a boot that is already filled with grease and bearing surfaces that have been polished to make them less slippery and quieter. The action stays quiet and smooth even when it's loaded because the grease pockets are sealed and the tolerances are very good.

High Load Capacity

Static loads of up to 36,400 N and high yield strengths, like 26,900 N for BL16BD, can be handled by THK BL joints. Because of their heat-treated steel balls and strong alloy holders, they don't get tired or bend.

Compact Precision

There is almost no play because the design makes very little radial spherical clearance (0.02–0.06 mm). Its tight fit helps with damping and accuracy, which are important for precise automation and sensing.

Excellent Durability

Steel and zinc/aluminum alloys that have been treated with chromate are the most resistant to wear. When boots are sealed to keep dirt and oil out, the life of the parts in extreme conditions is greatly extended.

Easy Maintenance

The BL series is easy to take care of because it comes pre-lubricated and sealed. This "lifetime lubrication" design does away with the need for outside grease fittings and regular relubrication. This lowers maintenance costs and downtime.

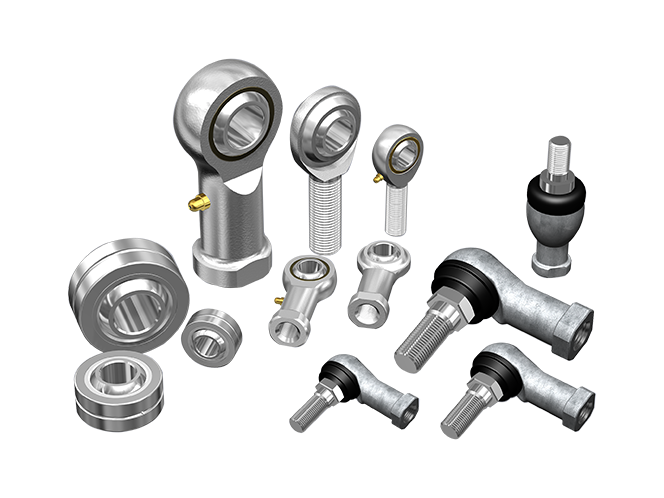

More Products

BL 12BD Link Ball

A mid-size double-threaded model (M12×1.75) that offers robust load capacity (static 26,700 N). Ideal for moderate-duty linkages with limited space.

BL 4DA Link Ball

Ultra-compact design with M4×0.7 thread, for tiny actuators or sensors. Its aluminum alloy holder (BL-A series) keeps it lightweight yet strong.

BL 12D Link Ball

Standard male-threaded (M12×1.25) joint for medium loads. Combines precision (0.02–0.06 mm clearance) with sealed grease for smooth operation.

BL 10BD Link Ball

Double-threaded (M10×1.5) version of BL10. Balances strength with compact size. Useful for tight assemblies needing high lubricity in oscillating motion.

BL 10D Link Ball

Single-threaded (M10×1.25) model. Known for reliable performance in machinery and valves, with corrosion protection from chromate plating.

BL 8D Link Ball

Small (M8×1.25 thread) joint. Dimensions are just 45.5×19 mm, making it suitable for lightweight linkages. Its compact size and tight tolerances ensure precise control in small mechanisms.

BL 6D Link Ball

Very compact (M6×1) joint for minor loads. An affordable, lightweight option that still features THK’s high-precision steel ball and pre-filled grease for quiet operation.

BL 5DA Link Ball

M5×0.8 double-thread variant in the most petite sizes. Its precision-fit housing and boot sealing make it great for tiny robots or precision instruments.

RBI 5D Link Ball

A female-threaded (“rod end”) version of BL5. The high-strength zinc alloy holder and sealed design enable it to withstand loads in line with the holder.

RBI 16BD Link Ball

Heavy-duty rod end with M16×2 internal thread. It can handle both compressive and tensile loads along the shaft axis, thanks to its dual threaded design and strong materials.

RBI 16D Link Ball

Similar to RBI 16BD but with a standard right-hand M16×1.5 thread. Suitable for industrial applications that require a female mounting end.

RBI 14BD Link Ball

Robust female thread (M14×2) variant with 36,400 N capacity. Provides a direct, threaded connection in automated link mechanisms.

RBI 14D Link Ball

M14×1.5 female thread joint for medium loads. Its sealed construction and high endurance make it a durable choice for assembly and transport equipment.

RBI 12BD Link Ball

M12×1.75 female-threaded link ball, high-strength zinc alloy housing. Offers stable performance in conveyor or guide link supports.

RBI 12D Link Ball

M12×1.25 female thread, standard design. Excellent for robotic arms and fixtures where space is limited.

RBI 10BD Link Ball

Female M10×1.5 thread. Compact yet robust, often used in pneumatic actuators and control linkages.

RBI 10D Link Ball

Female M10×1.25 thread. Lightweight design suits delicate applications while maintaining the same sealed lubrication feature.

RBI 8D Link Ball

Female M8×1.25, small size for precision instrumentation. Boots protect internal grease, ensuring smooth action in small pivots.

RBI 6D Link Ball

Smallest female link ball (M6×1). Ideal for hobbyists or prototyping applications that require low noise and easy assembly.

Suggested Product Types

Both types give a smooth, strong, and long‑lasting surface for seals. Regardless of the size of your shaft, SKF has a sleeve that suits your needs.

THK BL / BL-BD Series

The THK BL / BL-BD series includes regular ball joints with either a male threaded holder (BL) or a double-thread holder (BL-BD). They are THK’s main series and use a holder made of a strong zinc alloy and a steel ball. Choose BL-BD (with “L” for left-hand) if you want a joint with both a male and female thread.

THK BL-A Aluminum Link Ball

This version is lighter because it has an A-1 aluminum alloy holder. It is a great choice for robotics and car parts because it is light and strong at the same time. The only sizes that come in BL-A are BL4DA and BL5DA.

THK RBI Series (Female Holder)

Integrated rod-end bearings with a female-threaded holder that lines up with the ball shank axis. The design can handle both lateral and axial stresses (tension and compression). The application needs the threads of the bolts to line up. It is very resistant to wear thanks to its grease seal, which is the same as the BL series.

THK BJ Series (Ball Joint)

You could also check out THK’s BJ series of ball joints, like the BJ12H. Instead of the usual round rod ends, these have ball studs. The BL series is smaller overall because it was made to work with link mechanisms. BJ joints also make the steering and suspension system more flexible.

Custom-Engineered Solutions

THK and NOKS may be able to make custom link ball solutions for you based on your needs. You can change the thread size, shank length, and ball diameter through dimensional ordering to fit certain link lengths. You can choose between balls made of stainless steel or balls coated with a certain material. You can replace the NBR boots with rubber boots made from fluoro or silicone for use in places with high temperatures or chemicals. You can also change how often you lubricate. Our experts can change the ball’s hardness and plating to make it more resistant to corrosion. Nickel or trivalent chromate are two options. We can make a THK BL Link Ball just for you by changing these settings.

Interactive Size / Selector Tool

THK has an online tool that can help you pick the best link ball model. You can use the Optimal Product Selection Tool to find a THK Link Ball or rod end bearing model that fits your needs by entering the load, orientation, and environmental variables. The tool also gives you CAD drawings and estimates of how long things will last. We’ve added an interactive size selector to help you pick the best THK series for your design. Engineers can use this free tool on THK’s website to make it easier to choose products.

Industries and Applications

Industrial Automation & Robotics

The BL connect Ball is the best way to connect motion in machines and robots. It has sealed lubrication and is very accurate, so it’s perfect for assembly lines, packing, and pick-and-place systems.

Automobile (Height and Load Sensors)

THK BL Link Balls are used in the rod ends and linkage joints of automotive suspension height sensors. They are quiet and last a long time. These automobile height sensor rod ends are great for use in places where there is moisture and road debris because they have a chromate coating and a sealed boot.

Machine Tools & Precision Instruments

The BL joint has a spherical slide bearing ball stud interface with very little play, which makes it perfect for CNC machines and measuring tools. Their high wear resistance makes sure that the accuracy of the instruments lasts a long time.

Transport & Conveyors

The BL is a great part of material handling systems used in transportation and conveyors because it can handle misalignment without squeaking and can handle pulling and pushing loads (especially RBI female varieties).

Medical & Assistive Devices

The small THK BL-A aluminum link balls are used in medical robots and adjustable equipment because they are light and quiet, which are important for these devices.

Aerospace & Defense

Lightweight metals and the right high-temperature greases make it possible to make BL versions that work with aircraft link mechanisms. The precise fit of aircraft control systems helps them meet strict tolerances.

THK BL Link Ball Specifications

Both types give a smooth, strong, and long‑lasting surface for seals. Regardless of the size of your shaft, SKF has a sleeve that suits your needs.

Model

Thread

Ball Dia. (mm)

Static Load (N)

Yield Strength (N)

BL 14D

M14×1.5

21.9

36,400

19,800

BL 14BD

M14×2

21.9

36,400

19,800

BL 16D

M16×1.5

25.4

36,400

26,900

BL 16BD

M16×2

25.4

36,400

26,900

Advanced Abilities of THK BL Link Ball

Low-Friction Ball Surface

The THK BL Link Ball has a low-friction surface thanks to a steel ball that has been polished to a high level of accuracy. It runs on lithium soap grease and has very small tolerances. Using this internal lubricant with the sealed NBR boot cuts down on noise and contact between metal and metal. So, there is no chattering or sticking when the joint moves.

Thermal Stability

Even when exposed to very high or very low temperatures, the THK BL Link Balls are made to stay flexible and undamaged. The standard models are said to work between -15°C and 80°C. Using the special rubber boot and lithium grease keeps the joint working well with low friction across this range.

Corrosion-Resistant Engineering

The THK BL series is made to resist rust by treating the steel parts and using materials that will last a long time. The carbon steel ball shank is chromate-plated to keep it from rusting and corroding. The zinc alloy (or aluminum) holder won’t rust, even in very humid or wet conditions.

Basic Functional Structure

Smart Design

The THK BL Link Ball is small, but its smart design makes it easy to store. Putting the holder at an angle to the shank makes the structure work better by making a direct load path. The spherical area (top and bottom) has grease reservoirs that keep the ball greased at all times, so there is no need for outside fittings.

Durable Manufacturing

Every THK BL Link Ball goes through a full quality control process during the whole manufacturing process. The steel ball has been heat-treated and machined to exact spherical specifications, which makes it very hard to wear down. The casing is made of tough alloys that can be cast or machined. They don't get tired or break easily. In order to prevent any possible contamination, all parts are put together in a clean environment. THK checks the link ball for the right yield-point strength after it has been put together.

Precision Fit

THK's A Perfect Fit BL Link Balls are made with great care to make sure they fit snugly in their holders. The smallest spherical clearance (radial, 0.02–0.06 mm) shows that the joint is not loose at all. Because it fits so well, it won't rattle or move wrong. For machines that need to be very precise, this means that their movements are both repetitive and predictable.

Certification and Quality

THK is dedicated to keeping high standards of quality. To make sure everything is of high quality, the company checks the size of each part and has ISO 9001 certification. The BL series meets or exceeds the thread and fit standards set by JIS. THK and NOKS keep all the paperwork they need for certification, traceability, and conformity reports. Customers trust the BL Link Ball completely because it is made using a strict quality system and works as well as THK’s reputation for reliability.

Why NOKS International Trade Group Limited

NOKS International Trade Group Limited is a good place to get THK products. We carry a lot of THK products, including the THK BL Link Ball series, and we offer top-notch technical support for all of them. We know a lot about these parts, so we can help you pick the best model for your needs based on load, size, and use. We ship quickly all over the world, and our prices are low. NOKS is an authorized provider that guarantees the quality and warranty of THK products. When you work with NOKS, you get THK products along with help from local service and knowledge from around the world. If you need high-performance THK Link Ball Joints, Noks Supply is the place to go, whether you want to buy them off the shelf or have them made just for you.

FAQs

What is the static load capacity of the THK BL12BD?

The THK BL12BD (M12×1.75, double thread) can handle a static load of about 26,700 N, whether it’s pulling or pushing. The material’s Radal PK, or yield-point strength, is 16,400 N. In practice, this means that it won’t change shape when it weighs about 2.7 tons.

Which model should I use, BL or BL-BD?

Can an automobile height sensor rod end accept a THK BL Link Ball?

What makes THK BL and THK BL-A Link Balls different from each other?

Can you tell me what parts go into THK BL Link Balls?

How similar are other ball joints to THK BL Link Balls?

Customer Reviews

Michael Thompson

We installed the THK BL 8D in our small robot arm and it performed flawlessly. The movement is incredibly smooth and truly low noise. The compact size was perfect for our design. Overall, very satisfied.

Liu Wei

This is the quietest link ball I’ve ever used. In our height sensor application, the THK BL joint eliminated clatter. High precision and great build quality. NOKS delivered quickly and answered all my questions.

Michael Thompson

We installed the THK BL 8D in our small robot arm and it performed flawlessly. The movement is incredibly smooth and truly low noise. The compact size was perfect for our design. Overall, very satisfied.

Michael Thompson

We installed the THK BL 8D in our small robot arm and it performed flawlessly. The movement is incredibly smooth and truly low noise. The compact size was perfect for our design. Overall, very satisfied.

Michael Thompson

We installed the THK BL 8D in our small robot arm and it performed flawlessly. The movement is incredibly smooth and truly low noise. The compact size was perfect for our design. Overall, very satisfied.

Michael Thompson

We installed the THK BL 8D in our small robot arm and it performed flawlessly. The movement is incredibly smooth and truly low noise. The compact size was perfect for our design. Overall, very satisfied.

Noks Bearing is proudly powered by WordPress